Yes, the design has been honed (no engineering pun intended) and refined to within an inch of it's life and even different shapes have been experimented with, to good effect (oval pistons in Japanese racing bike engines, like Honda in 1979 with the 500cc NR500 Grand Prix racer for example) but its fair to say even the likes of Étienne Lenoir or Gottlieb Daimler could recognise a modern piston, so fundamental is the design. But Felix Wankel's engine design would be something that may be alien to them.

The rotary engine, with its rotary piston design owes little or nothing to the traditional internal combustion engine. Wankel received his first patent for the engine in 1929, began development in the early 1950s at NSU, and completed a working prototype in 1957. It became a mainstay of NSU and Mazda cars for many years (licences were granted to Mazda and others, including Mercedes-Benz, Citroen, Norton, GM, Ford and even the likes of Alfa Romeo, American Motors, Nissan, Porsche and Rolls-Royce, among others),with the design flaws that have plagued the engine for many years seemingly ironed out. One of the brilliant aspects of the rotary engine is that increasing the displacement and power of a Wankel engine is straightforward, by adding more rotors. It was thought that a limit may exist in the total number of rotors that could be added, as power output is channeled through the last rotor shaft, with all the stresses of the whole engine present at this point. Up to now, the maximum size that a manufacturer has produced has been (I think) the four-rotor engine used in the Mazda 787B Le Mans car of the early 90's.

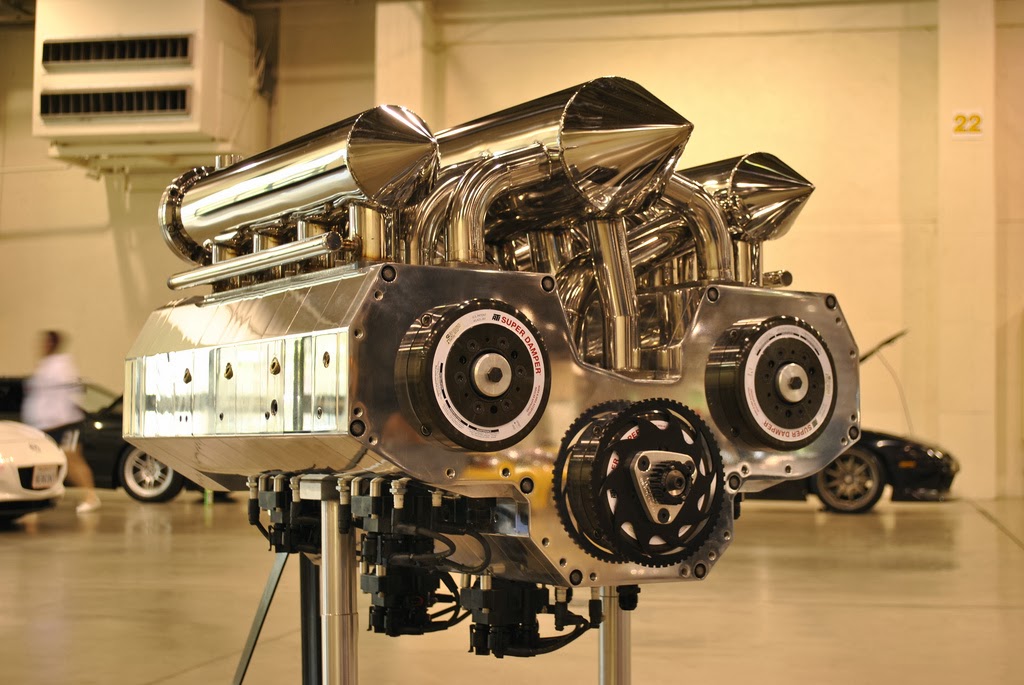

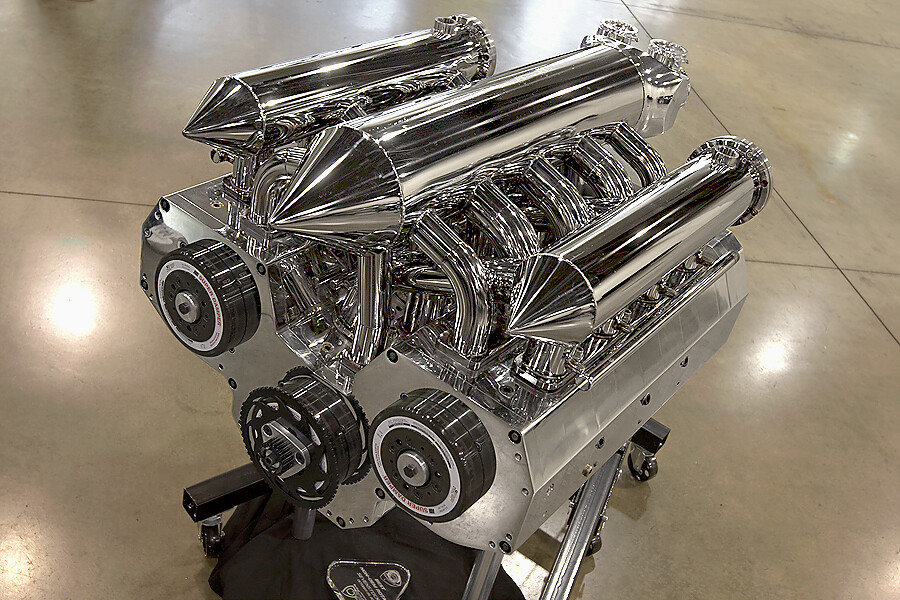

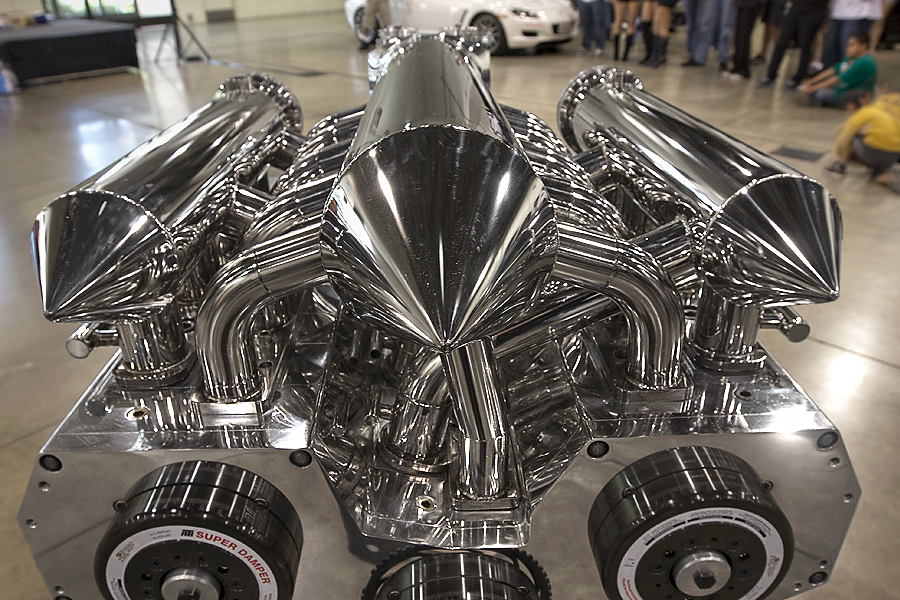

But that hasn't stopped ingenious individuals proving the theory wrong, like Tyson Garvin. He is an endurance powerboat racer who has twice set the record for the run from New York City to Bermuda, and he’s built a 12-rotor Wankel engine. The three banks of four rotors are arranged in a Y-configuration and are kept in sync with each other by a set of gears. It displaces a massive 15.7 litres, yet externally it’s about the same size as your average American big-block V8. And to whet your appetite further, Garvin has confirmed that his company Apex Manufacturing and Design LLC are building a 12-rotor engine for a supercar to hopefully break some land speed records.

The one you see in the pictures is for marine use, naturally aspirated on 87 octane pump petrol; its said to make 1440hp and 900lbs/ft of torque and will do so for 400 hours of use. With turbocharging, it is meant to be capable of an incredible 3600bhp. And the icing on the cake is that the engine is so smooth, that even glasses of water placed on the engine (as seen in he video) show little sign of rippling.

Sign me up for the rotary club please.

- Amazosan

And now, the live-action rotary madness:

No comments:

Post a Comment